|

|

|

|

|

|

Enter Your E-Mail to receive

our Free monthly newsletter.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DESCRIPTION

The Integra® Wall System is an engineered and post-tensioned masonry wall system that is used in either load bearing or nonbearing conditions. The Integra® Wall System uses masonry units that are usually open on both ends and a reduced center web to reduce thermal bridging. However, there may be times when other special units may be used, as in the case of architectural faced units.

REINFORCING SYSTEM

|

| Figure 1 |

The Integra® System is reinforced using post-tensioning technology along with, at times, conventional methods of reinforcing. Vertical reinforcing consists of 7/16” high tensile strength steel rods that are rolled threaded at each end. These rods, depending upon the height of the wall, may be a single length rod or may be in multiple sections. They are connected to the proprietary anchor bolts, which are placed in a conventional concrete or masonry foundation. Horizontal reinforcing may include conventional joint reinforcing when determined by the structural engineer that it is necessary.

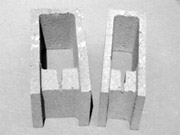

Once the walls have been erected, the walls may now be tensioned. There is a special plate bearing block that is used on the last course at each of the tension rods, or as noted on the drawings. (These may or may not be used such as in the case of special or architectural faced block.)

|

| Figure 2 |

These are usually special units containing a 5/8” slot through which the tension rod extends. (See Figure 2) The tension assembly sits in a recessed pocket in the masonry unit that is designed for this purpose. (See alternate tension detail under “Wall Sections”.) The tension assembly consists of a ˝” steel plate washer, standard hardened washers, and a Direct Tension Indicator Washer, (See Figure 4 of System Application) The DTI washer is manufactured specifically for the Integra® System, and is used to verify the level of post-tensioning force on the rod.

|

INSULATION

|

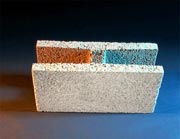

| Figure 3 |

When optimum thermal performance is required, proprietary polyurethane, specifically blended for use in the Integra® Wall System, is used. (Figure 3) (There may be occasions where insulation is not a consideration and, therefore, no insulation may be installed.) After the walls have been insulated, excess material is removed, leaving the top of the wall flush.

|

BENEFITS

The Integra® System was designed to offer all the benefits of a conventional masonry wall system, while at the same time providing superior thermal performance properties. The Integra® System is a system that can easily be erected by any masonry contractor. The post-tensioning of the walls, the installation of the polyurethane insulation, when used, as well as all of its specified components, remain in the hands of Superlite Block, or appointed licensees, thus maintaining the necessary level of quality control.

The Integra® System is designed to be used in all types of residential, as well as commercial projects. The use of the Integra® System will require a registered structural engineer to provide the necessary shop drawings and analysis to ensure its proper use and design.

The Integra® System is protected under U. S. Patent #’s 5,138,808 and 5,007,218 and is a registered trademark of Superlite Block.

|

|

|

|

|

|

|

|

|

|

|

|

|

|